Groundbreaking technology

Plasma catalysis:

Efficiency redefined

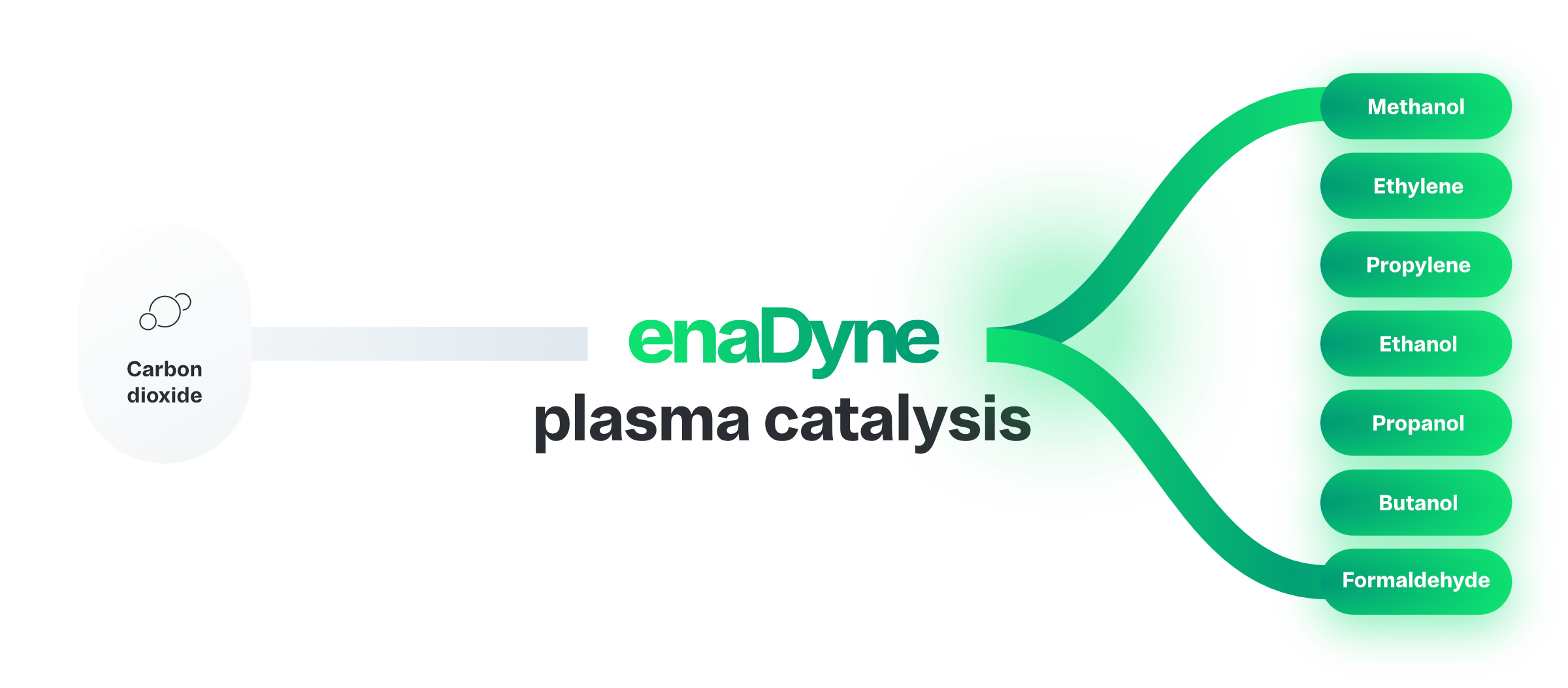

enaDyne's technology revolutionizes the production of chemical feedstocks by using cold plasma in combination with our patented enaCeramics electrodes. This method efficiently transforms CO2 into valuable chemicals using customized catalysts. Our processes are characterized by high efficiency and selectivity while offering considerable flexibility and scalability for a wide range of applications.

In a single process step, the basic building blocks of modern carbon chemistry are created from CO2 - sustainably and completely without fossil components.

Plasma

Inside our reactors, we ignite a cold plasma at temperatures between 50 °C and 150 °C at ambient pressure, which we use to energize the CO2.

Catalysis

The increased reactivity due to the plasma enables the direct conversion of CO2 with the help of our special catalysts - without splitting it first and without coupling in additional heat.

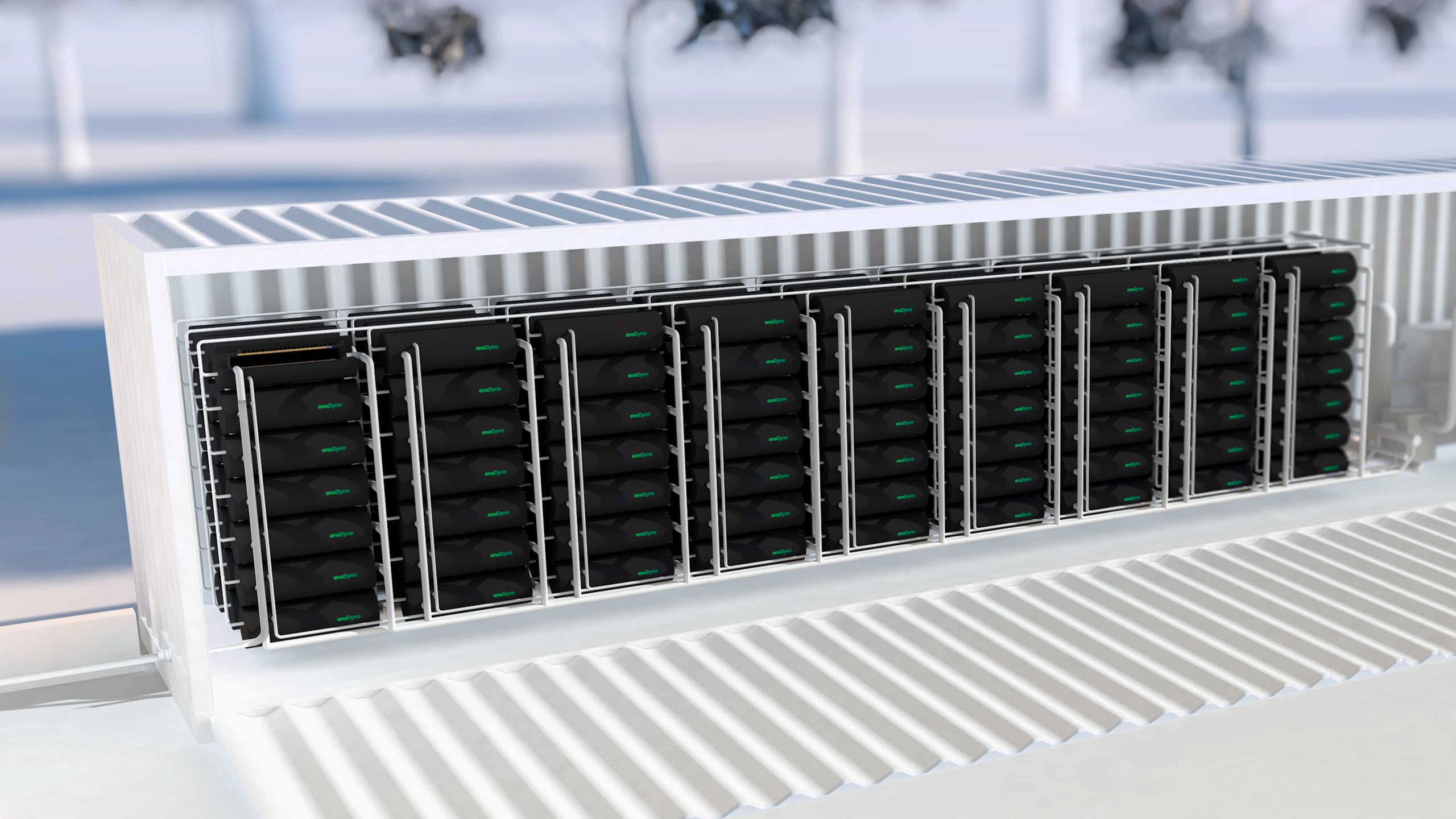

Container

Thanks to its modular design, the technology can be efficiently scaled and seamlessly integrated into any value chain as a plug-and-play solution.

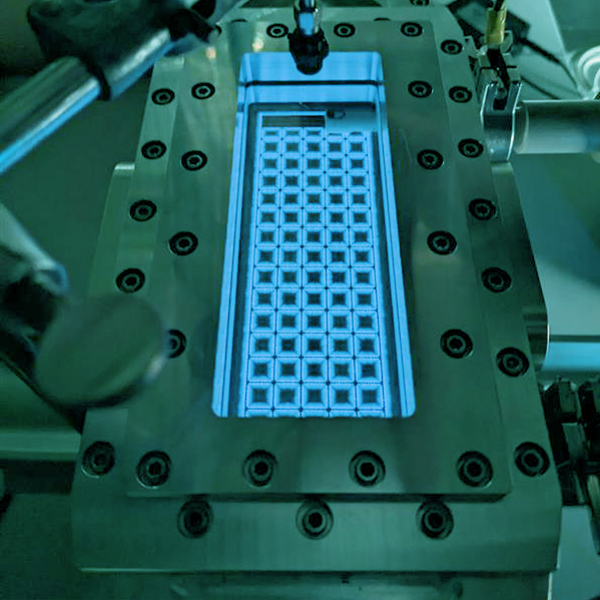

Leading thanks to enaCeramics electrodes

With our patented enaCeramics electrode technology, plasmas can be ignited more efficiently. The resulting reaction stability results in higher efficiency and selectivity. In addition, enaCeramics electrodes offer high chemical abrasiveness and adaptable surface properties for long reactor lifetimes.

The material also enables significant increases in performance in other applications such as emission filters.

Philipp Hahn

Co-Founder and CEO

We will be happy to answer your questions about our technology or a collaboration.

Change the world with us!

Are you interested in our technology or its application? We will be happy to answer all your questions.