Industrial application

Flexible use in various industries

Regardless of whether companies are active in the biogas sector, in industrial point sources or in the energy sector, enaDyne always offers an optimal and individual solution. The enaDyne technology is flexible and can easily be used in different industries.

The enaDyne technology processes the raw, unseparated biogas at biogas plants. This not only increases the output volume but also the added value per unit and increases profitability by a factor of 4 - 8.

With enaDyne technology, steel and cement plants will become the producers of chemical raw materials of tomorrow. A single plant could thus be able to cover the needs of entire chemical parks.

By utilizing the numerous CO2 point sources within their value chains, chemical producers can lower their demand for fossil raw materials with enaDyne technology and significantly reduce their emissions.

The switch to renewable energy generation means that a wide range of storage options are becoming increasingly important. Due to the switch-on and switch-off times of just a few minutes, grid fluctuations can be absorbed with the flexible enaDyne reactors and used to generate chemical energy storage, for example.

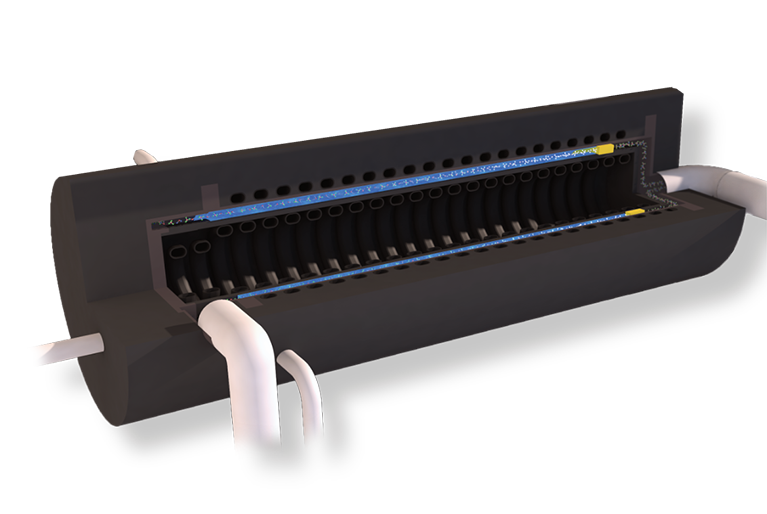

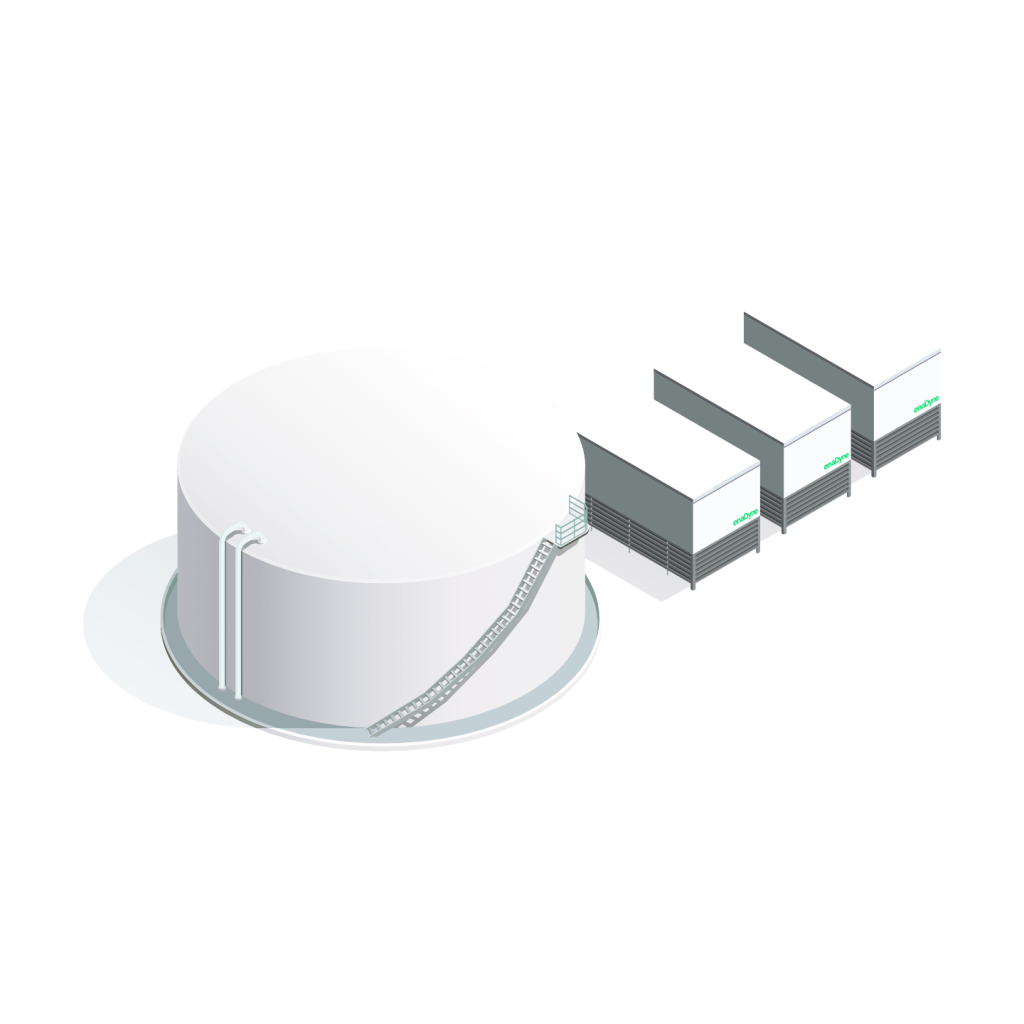

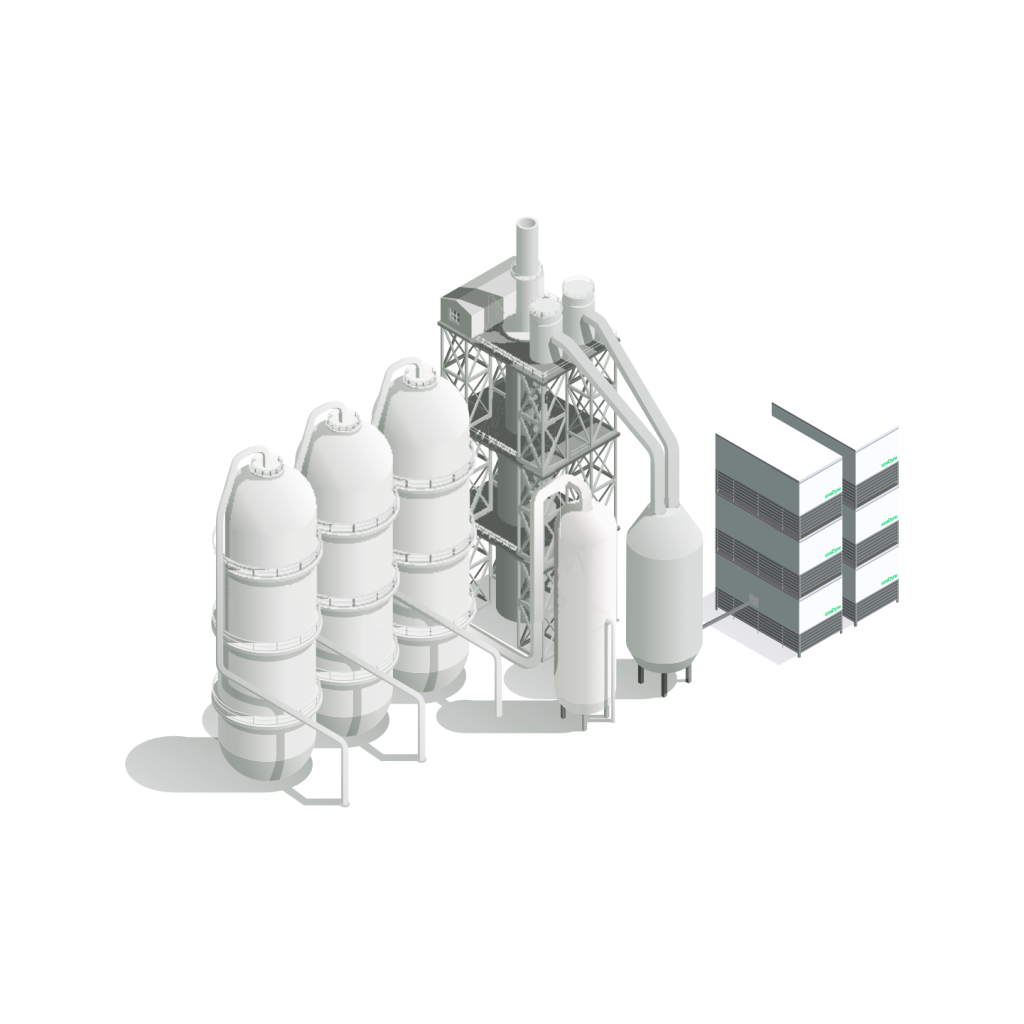

Case study biogas plant

Most biogas plants try to increase profitability by increasing the methane or energy output. The CO2 generated during production is often overlooked due to its carbon neutrality. enaDyne technology uses the unseparated biogas and processes CO2 and CH4 into higher-priced hydrocarbons.

Philipp Hahn

Co-Founder and CEO

We will be happy to answer your questions about our technology or a collaboration.

Change the world with us!

Are you interested in our technology or its application? We will be happy to answer all your questions.